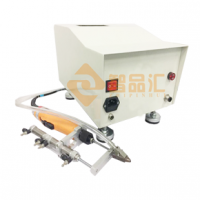

ZH-CZ-5331X 精準4軸4-axis | |

加工范圍Processing range X/Y/Z/R | 300mm/300mm/100mm(可定制Customizable) |

Y軸平臺最大負載Y-axis platform maximum load | 15KG |

XY/Z axis軸移動速度movement speed (mm/sec) | 0-1200 |

XYZ軸重復精度XYZ Axis Repeatability | <± |

控制方式Control Mode | PLC/工業控制卡PLC/Industrial Control Card |

編程方式Programming method | 觸摸屏/手持編程器Touch screen / handheld programmer |

程序記錄容量Program recording capacity | 999組程序999 programs |

馬達系統Motor system | 步進級精密馬達Stepping precision motors |

傳動方式Transfer method | 高精度同步帶或精密級絲桿+直線導軌.High precision synchronous belt or precision grade wire rod + linear guide rail |

電批Electric batch | 奇力速Kilews (Customers can also specify) |

輸入電源Input power | AC220V(內部開關轉換Internal switch conversion) |

工作環境溫度Working temperature | 5-40℃ |

外形尺寸Dimensions | L680*W760*H820 |

機器重量Machine weight | 75KG |

功能和特點Functions and characteristics

1、電批帶螺絲滑牙、浮鎖檢測功能的系統:當螺絲打不良(漏鎖、滑牙、浮鎖)時,系統會自動暫停并且報警.Electric batch system with screw sliding and floating lock detection function: When the screw is bad (leak lock, slide tooth, float lock), the system will automatically pause and alarm.

2、強力的吸嘴,確保每次都吸起螺絲.Strong suction nozzle, make sure to - the screws every time.

3、螺絲通用性強,只需調整軌道,更換吸嘴、批頭即可適應-M4的螺絲鎖附.The screw has strong versatility, only adjust the track, replace the suction nozzle, and the batch head can adapt to the screw lock attachment of M0. 8-M4.

4、雙Y軸設計、交替作業、無產品取放時間、實現生產效率最大化.Double Y-axis design, alternate operation, no product take-up time, realize maximum production efficiency.